This guest blog post was written by Martin Ross, product manager for UniSim Competency Suite at Honeywell Process Solutions. This is part two of a two-part series. Click here to read part one.

Developing and maintaining competent process operators is critical to business performance in the process industries. This blog post, the second part in a two part series, looks at operator competency. In the first post I focused on four signal classes that are leading and lagging indicators of potential competency gaps in process operators. In this post I look at how to close the competency gap.

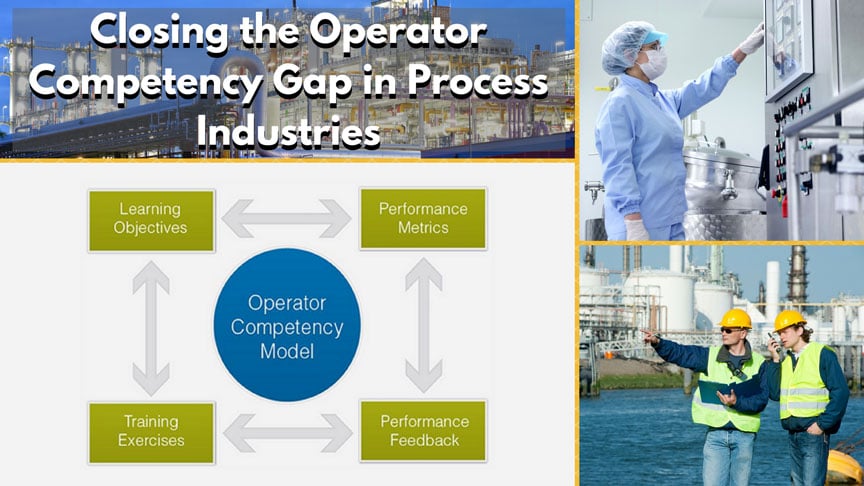

Operator performance evaluation framework

To close competency gaps it is necessary to use some form of framework of evaluation and intervention. The framework provides a consistent approach and a mechanism for sustaining the benefits into the future. A recommended framework is based on continuous performance evaluation. For example, a new hire typically receives initial classroom training on the basics skills of an operator. This first training could include an introduction to some of the advanced skills that would be acquired through on the job experience and mentoring by experienced colleagues. During this stage the new operator is subject to continuous performance monitoring to identify any short falls in specific competencies. Monitoring could be triggered by a number of conditions such as observation that variables are deviating from expected values or analysis of incidents that occurred. During this early phase the new operator would typically display a wide variation in performance from expected norms. The variation is expected to reduce over time until at some point the operator is judged to be “certified”. Once certified, the operator remains subject to continuous performance monitoring which will identify any drift away from expected performance norms. Refresher training triggered by events or by a standard schedule brings the performance back to the expected norm. This continuous performance evaluation is the key to sustaining optimal performance over time.

Competency-based evaluation and training

The evaluation framework provides an approach to drive towards optimal performance. The big picture pieces that are needed are:

- Deviation from expected norms

- Map deviation to a competency gap

- Provide training to close the gap

- Continue to monitor and close gaps that emerge

Central to this framework is a competency model for the process operators that permits the identification of the specific competency gap and suggests a training intervention. One way to address this is to look at the roles and responsibilities of the operator and identify competencies required and the level of proficiency in a particular competency required for a specific role. First, the responsibilities of a job function are identified. For example, in the case of console and field operators two key responsibilities are:

- Operate under normal conditions

- Anticipate and respond to abnormal conditions

Each responsibility is then broken down into a set of competencies. For example, the responsibility “operate under normal conditions” requires the following competencies:

- Operate unit controls

- Interact with other units

- Execute a shift handover

Next, each competency is linked to a set of associated behaviors, described in terms that can be measured. For example, the competency “operate unit controls” requires a console operator to exhibit the following behaviors:

- Explain unit control schemes

- Manipulate controls without adversely affecting the unit

- Troubleshot control loops

- Explain process chemistry and physics

Finally, each behavior learned by a trainee can be assigned a proficiency, ranging from ‘aware’ to ‘knowledgeable’, ‘skilled’ and ‘master’.

The operator competency model allows not only for the identification of gaps, but is also used to specify the training interventions needed to close the gaps. The learning and development team specifies interventions targeted at developing the competency and level of proficiency necessary for a particular role. Following the model is pertinent to decrease the risk of non-optimal outcomes leading to reduced performance or even worse business failure.

Click here to read part one of this two-part series.

About the Author Martin Ross is Honeywell Process Solutions product manager for UniSim Competency Suite. Martin has spent 25 years supporting customers with operator training solutions based on advanced simulation technologies. Martin earned BSc and Ph.D. degrees in chemical engineering from Imperial College in London, UK.

Martin Ross is Honeywell Process Solutions product manager for UniSim Competency Suite. Martin has spent 25 years supporting customers with operator training solutions based on advanced simulation technologies. Martin earned BSc and Ph.D. degrees in chemical engineering from Imperial College in London, UK.

Connect with Martin: