AutoQuiz is edited by Joel Don, ISA's social media community manager.

This automation industry quiz question comes from the ISA Certified Control Systems Technician (CCST) program. Certified Control System Technicians calibrate, document, troubleshoot, and repair/replace instrumentation for systems that measure and control level, temperature, pressure, flow, and other process variables. Click this link for more information about the CCST program.

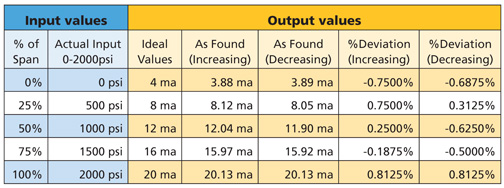

An electronic differential pressure (DP) cell and pressure transmitter device has been suspected of reading incorrectly during some high-pressure plant operations. The instrument supervisor sends the best technician during the next shutdown to diagnose the problem. The as-found condition of the pressure transmitter as recorded by the instrument technician has given the values shown in the post graphic.

What should the instrument technician report to the supervisor?

a) there is no apparent problem with the pressure sensor/transmitter

b) the pressure sensor/transmitter is giving a non-linear response; replacement of the sensor and/or the transmitter will be required

c) the pressure transmitter span has drifted; the pressure transmitter should be recalibrated

d) the pressure transmitter zero has shifted; the pressure transmitter should be recalibrated

e) none of the above

Response A (no apparent problem) would be appropriate only if the % Deviations calculated for the as-found conditions were all very close to zero (e.g., <0.01%).

Response C (span drift) would be indicated by % Deviations all increasing in the positive direction with a very small deviation (e.g., <0.01%) at the 0% value. In addition, the % Deviation for increasing and decreasing input values would need to be very close in value, indicating hysteresis is not a problem.

Response D (zero shift) would be indicated by % Deviations of roughly all the same magnitude, either (+) or (-), including the 0% values. In addition, the % Deviation for increasing and decreasing input values would need to be very close in value, indicating that hysteresis is not a problem.

From the table of as-found values, the % Deviations cross from positive to negative several times, indicating a non-linear response. In addition, the as-found % Deviation values as the input signal is decreased are quite different from the values found with increasing input signal, indicating hysteresis in the output signal. This may indicate the DP cell is damaged or the pressure transmitter electronics are not functioning properly.

The correct answer is B, the pressure sensor/transmitter is giving a non-linear response; replacement of the sensor and/or the transmitter will be required.

Reference: Goettsche, L.D. (Editor), Maintenance of Instruments and Systems, 2nd Edition

About the Editor

Joel Don is the community manager for ISA and is an independent content marketing, social media and public relations consultant. Prior to his work in marketing and PR, Joel served as an editor for regional newspapers and national magazines throughout the U.S. He earned a master's degree from the Medill School at Northwestern University with a focus on science, engineering and biomedical marketing communications, and a bachelor of science degree from UC San Diego.